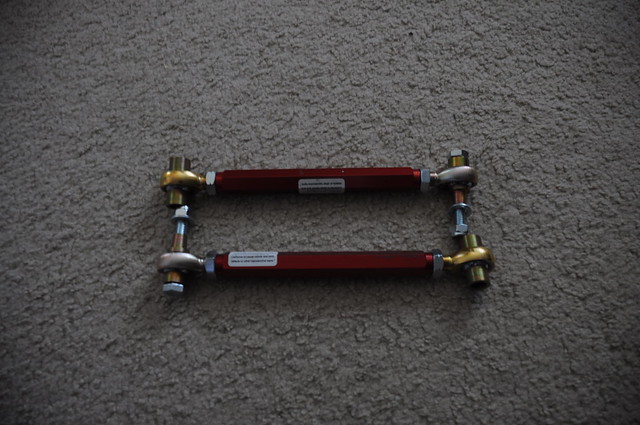

Things were looking up, Parts had been rolling in and found their way onto the subframe. I somehow forced the subframe, arms, and hubs onto dollies and pushed them back into the garage under my car to await the last few remaining parts, the BVer Toe rods and BVer subframe mounts.

On my day off, I headed over to Battle Version. After slamming my tC's underbody about 30 times through horrific Pomona streets, we arrived in the plaza where Battle Version had apparently just moved into. Walked up to the shop and was greeted by a Alex Pfeiffer from inside. Walked in and greeted him, and asked for the parts. As I waited for the toe rods to get assembled, Alex went thoroughly over the subframe mounts, explaining which one went where. After a quick chat and tour through his shop, we headed to Home Depot to pick up bolts/nuts for exhausts, and off to IHop for a quick lunch. Arrived back home and got right to work. Threw the BVer stuff in the freezer, since they seemed to be a bit of a tight fit already, and while we waited for the aluminum to compress a bit, we made sure everything else on the subframe was nice and tight. An hour or two later, took the mounts out and slammed them into the mounts with a deadblow since I hadn't deburred the rear subframe mounts completely of the burnt rubber.

On my day off, I headed over to Battle Version. After slamming my tC's underbody about 30 times through horrific Pomona streets, we arrived in the plaza where Battle Version had apparently just moved into. Walked up to the shop and was greeted by a Alex Pfeiffer from inside. Walked in and greeted him, and asked for the parts. As I waited for the toe rods to get assembled, Alex went thoroughly over the subframe mounts, explaining which one went where. After a quick chat and tour through his shop, we headed to Home Depot to pick up bolts/nuts for exhausts, and off to IHop for a quick lunch. Arrived back home and got right to work. Threw the BVer stuff in the freezer, since they seemed to be a bit of a tight fit already, and while we waited for the aluminum to compress a bit, we made sure everything else on the subframe was nice and tight. An hour or two later, took the mounts out and slammed them into the mounts with a deadblow since I hadn't deburred the rear subframe mounts completely of the burnt rubber.

Slammed in the front mounts and got a jack under the diff. As we jacked it up, we lined it up to the driveshaft that had been chillin' it on a bar that runs across the bottom of the tranny tunnel. When they were lined up, I gave the subframe a quick few kicks from behind to force the diff into the driveshaft. Once that was in, we jacked it up the rest of the way and bolted everything in, including the toe rods since it was easier to install with the subframe already in the car.

Double checked to make sure everything's tight and Lowered the car back down.

Whoops. Rears ended up having positive camber and insane toe out.

Redo. Shortened the upper control arm and lowered it .5".

Redo. Shortened the upper control arm and lowered it .5".

Lowering it turned out to be a problem, as I had completely forgotten the rear coils hadn't been settled yet, and the cat converter under the car ended up smashing into the ground 30 times in a 3 minute test drive while my car was on the verge of rimtuck. Took off the kit for the time being, and went ahead and installed my new tanabe exhaust that I had gotten in a trade for my 5zigen fireballs. The fireballs didn't allow for a rear lip, and it had a look that I was slowly getting a bit tired of. Before another test drive, I, again, adjusted stuff.

During that process, I noticed the rear wheel had play in it. Uh oh. Checked to make sure loose nuts/bolts weren't the cause of it, but they were all tight. Took it for another drive, this time along a route that had walls lined along the right had side to listen for sounds. Sure enough, there was clicking that went faster as I gained speed.. Bad wheel bearing. Time to jack up the car yet again and have new bearings pressed in. Took off the hub and decided, this would be the optimal time for new brake shoes. Also, while my car's up on jacks, I might as well do what I wanted to do before, to shorten the LCA.

Can't wait to get some seat time in this thing once it's all back together with a proper alignment.

During that process, I noticed the rear wheel had play in it. Uh oh. Checked to make sure loose nuts/bolts weren't the cause of it, but they were all tight. Took it for another drive, this time along a route that had walls lined along the right had side to listen for sounds. Sure enough, there was clicking that went faster as I gained speed.. Bad wheel bearing. Time to jack up the car yet again and have new bearings pressed in. Took off the hub and decided, this would be the optimal time for new brake shoes. Also, while my car's up on jacks, I might as well do what I wanted to do before, to shorten the LCA.

Can't wait to get some seat time in this thing once it's all back together with a proper alignment.

RSS Feed

RSS Feed